In the world of electronics, creating a prototype of your printed circuit board (PCB) design is a crucial step in the product development process. However, the way you assemble your PCB prototype can significantly impact the outcome. In this article, we will explore the various methods available, why choosing the right prototype assembly method is essential, and factors to consider to make an informed decision.

What is a PCB Prototype Assembly Method?

Before we dive into the details, let’s clarify what a PCB prototype assembly method is. When you design a PCB, it’s essentially a blueprint for a circuit. A prototype assembly method is the process of bringing that blueprint to life by soldering the electronic components onto the PCB.

Why Choosing the Right Method Matters

Selecting the appropriate prototype assembly method is not just a technicality; it can have far-reaching consequences for your project. The right method can save you time and resources, and ensure the functionality and reliability of your design. Conversely, the wrong method can lead to errors, delays, and even failure.

- Complete Guide to Electronics Engineering

- Traction Control Sensor TCS: Working and Common Fault Signs

Prototype Assembly Methods Explained

Let’s take a closer look at some common prototype assembly methods:

Hand Soldering: A DIY Approach

Hand soldering involves manually soldering each electronic component onto the PCB. It’s a DIY-friendly method that works well for simple designs and one-off prototypes. This method allows for precision but can be time-consuming and may not be suitable for complex or high-volume projects.

Wave Soldering: The Conveyor Belt Solution

Wave soldering is an automated method where PCBs move on a conveyor belt, passing over a wave of molten solder that attaches to the components. This method is faster and more suitable for high volumes. It’s less precise than hand soldering and may not work well for designs with components on both sides of the PCB.

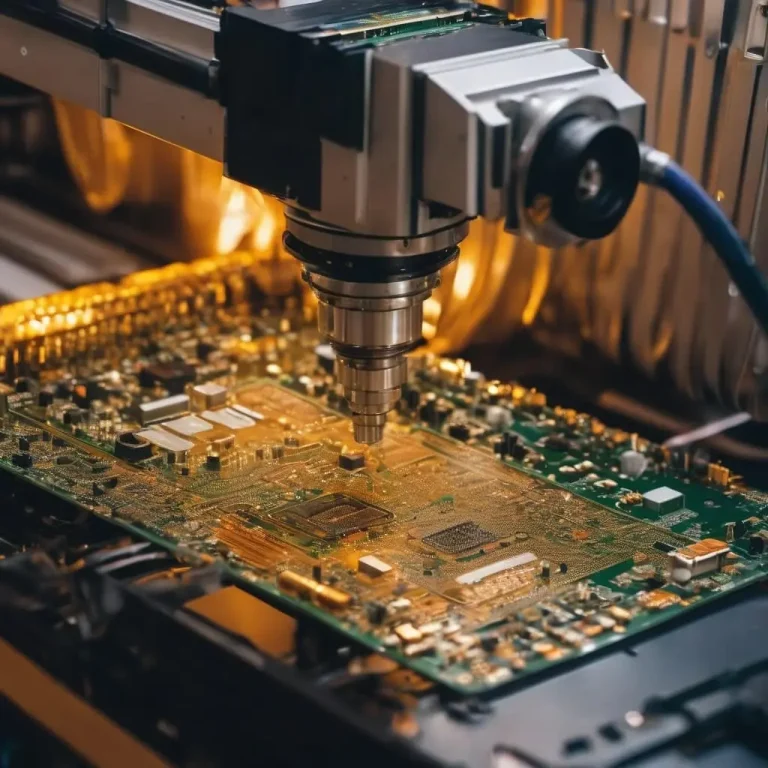

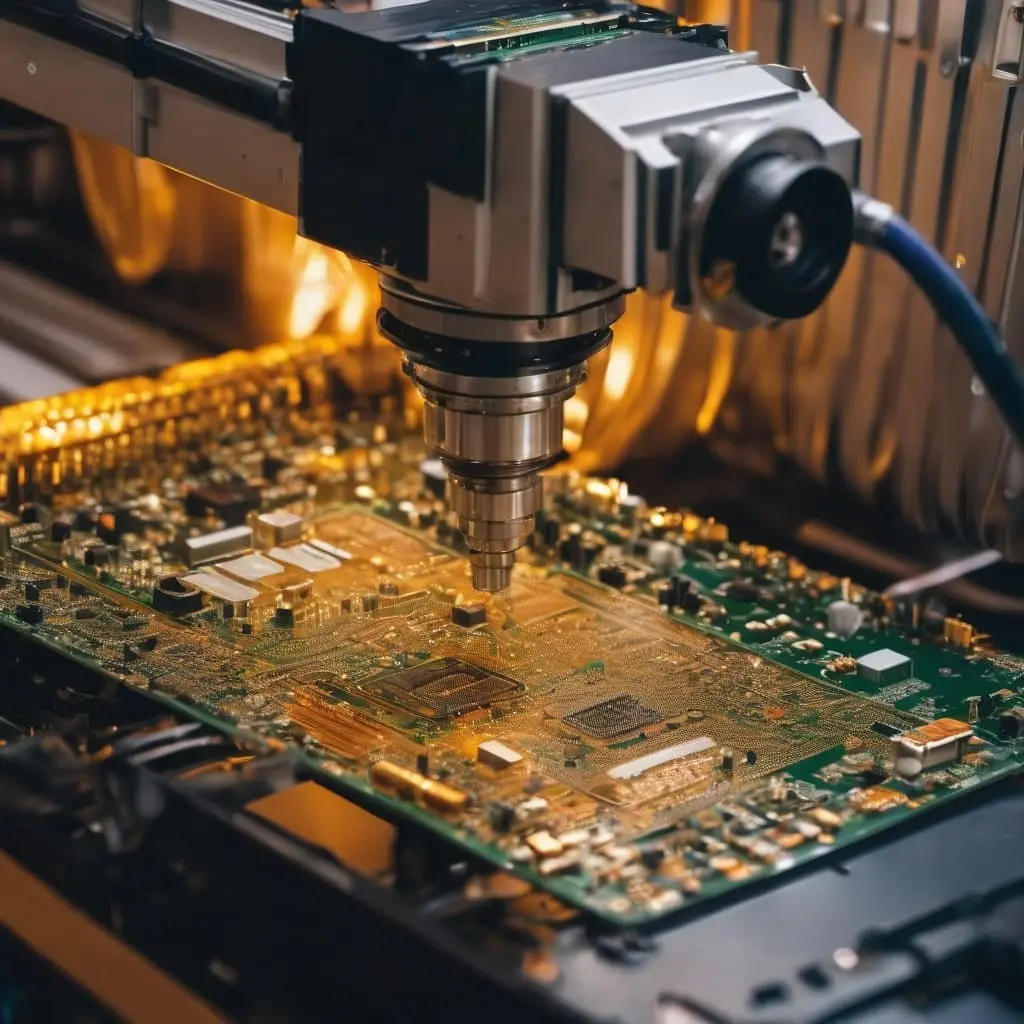

Reflow Soldering: Precision in Heat

Reflow soldering uses a controlled oven to melt solder paste, attaching components to the PCB. It’s precise and suitable for surface mount components. This method is commonly used in professional assembly services.

Key Factors to Consider

Choosing the right prototype assembly method hinges on several key factors:

Complexity of Your Design

The complexity of your design determines the assembly method. Hand soldering is perfect for simple projects, while complex designs often require automated methods.

Budget Constraints

Your budget plays a significant role in the choice of assembly method. Hand soldering is cost-effective but can be time-consuming. Automated methods are efficient but come at a higher cost.

Time Constraints

If time is of the essence, automated methods like reflow soldering may be the best choice. Hand soldering, while precise, takes longer.

Quantity of Prototypes

Consider the number of prototypes you need. Hand soldering works for a few prototypes, while wave and reflow soldering are better for large quantities.

- Complete Guide to Electronics Engineering

- Traction Control Sensor TCS: Working and Common Fault Signs

A Closer Look at Materials

The materials you use for prototype assembly are crucial. Consider:

Solder Paste

High-quality solder paste is essential for reliable connections. It’s crucial for successful reflow soldering.

Soldering Irons vs. Soldering Stations

For hand soldering, investing in a quality soldering iron or station is a must. It can make a significant difference in the quality of your work.

DIY vs. Professional Assembly

Tips for DIY Enthusiasts

If you’re a DIY enthusiast, here are some tips:

- Safety First: Work in a well-ventilated area and use safety equipment.

- Invest in Quality Tools: Quality soldering irons, flux, and soldering stations will make your work more manageable.

- Practice Makes Perfect: Don’t rush; practice your soldering skills on test boards before tackling your PCB.

Professional Assembly Services

For professional assembly, consider:

PCB Assembly Companies

These companies specialize in assembling prototypes and small or large production runs.

Online PCB Assembly Services

Many online services offer quick and efficient PCB assembly for a range of project sizes.

Choosing the Right Partner

When selecting a professional assembly service, weigh your options based on the following factors:

Cost Considerations

Upfront Costs

Consider initial setup costs and pricing per unit for small runs. These costs vary from one service provider to another.

Long-term Costs

If you plan for large-scale production, negotiate long-term costs to ensure affordability and scalability.

In conclusion, selecting the right prototype assembly method is a critical decision in your PCB design journey. Carefully assess your design’s complexity, budget, time constraints, and quantity requirements. Whether you opt for the DIY approach or professional assembly services, ensuring the quality of materials and equipment is vital. With the right assembly method and partner, you can bring your PCB design to life efficiently and effectively.