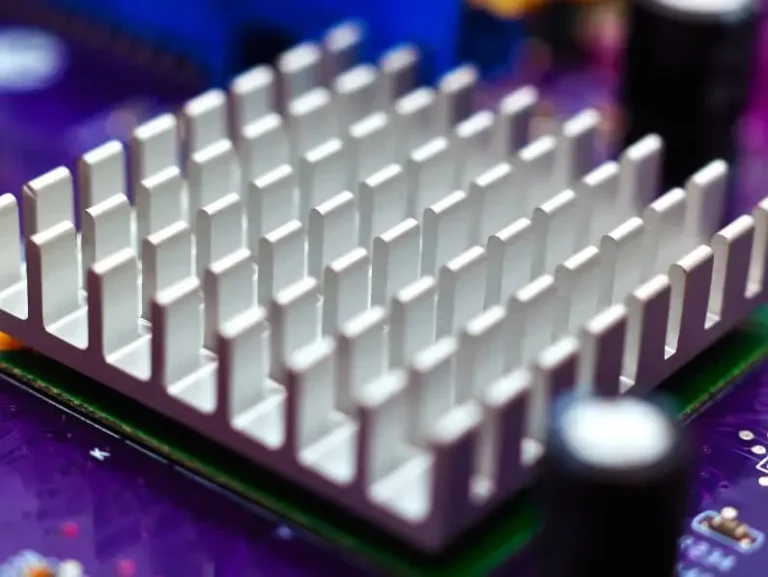

When it comes to keeping electronic devices cool, heatsinks play a crucial role. These passive cooling solutions dissipate heat generated by components, ensuring optimal performance and longevity. However, not all heatsinks are created equal. One of the key factors that decides the effectiveness of a heatsink is the material from which it is made. In this article, we’ll explore the best heatsink materials available and help you choose the right one for your application.

Copper:

Copper is perhaps the most popular choice for heatsink material, and for good reason. It boasts excellent thermal conductivity, meaning it can efficiently transfer heat away from the source. Copper heatsinks are also relatively easy to manufacture and are highly durable. While copper heatsinks tend to be more expensive than their aluminum counterparts, they offer superior performance, making them ideal for high-end applications where thermal management is critical.

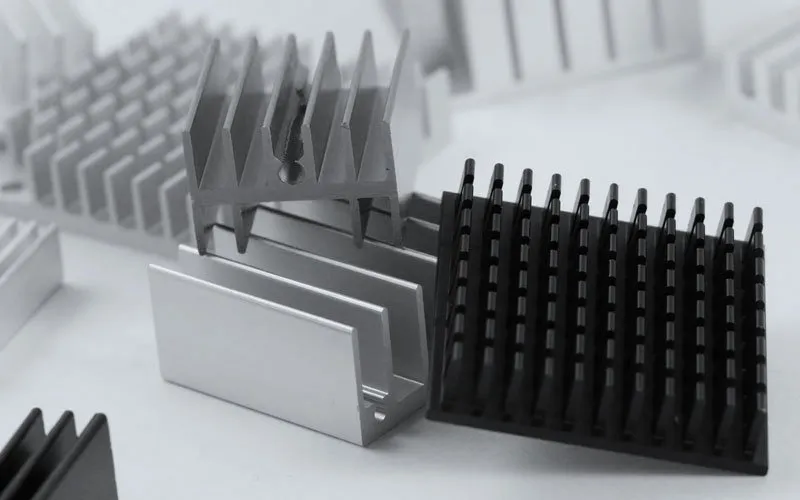

Type of Heatsink Material:

Aluminum:

Aluminum is another widely used heatsink material, prized for its lightweight nature and affordability. While not as thermally conductive as copper, aluminum still offers good heat dissipation capabilities, especially when designed with a large surface area or using heat pipes. Aluminum heatsinks are commonly found in consumer electronics and computer components, where cost-effective cooling solutions are preferred.

Copper-Aluminum Composite:

For those looking to strike a balance between performance and cost, copper-aluminum composite heatsinks offer a compelling solution. These heatsinks feature a base made of copper for optimal heat transfer, coupled with aluminum fins for lightweight and cost-effective cooling. This combination allows for efficient heat dissipation while keeping manufacturing costs in check, making them a popular choice for a wide range of applications.

Graphite:

Graphite heatsinks are a relatively newer entrant to the market but are gaining popularity due to their exceptional thermal conductivity. Graphite boasts thermal conductivity comparable to copper, making it an excellent choice for high-performance applications where space is limited. Graphite heatsinks are also lightweight and can be easily customized, offering designers flexibility in their thermal management solutions.

- Traction Control Sensor TCS: Working and Common Fault Signs

- Motion Encoder: Understanding How It Tracks Precision

Vapor Chamber:

Vapor chamber heatsinks utilize a sealed chamber containing a small amount of water or other liquid. As heat is applied, the liquid evaporates, spreading heat evenly across the chamber. Vapor chamber heatsinks offer excellent thermal conductivity and are used in high-performance computing and LED lighting.

Heat Pipes:

Heat pipes are another effective way to transfer heat away from electronic components. They consist of a sealed tube containing a small amount of liquid that evaporates at one end and condenses at the other. Heat pipes are often used in laptops, smartphones, and other compact electronic devices.

How to Choose the Right Heat Sink Type for Your Needs

Heat sinks are essential components in electronic devices, helping to dissipate heat and prevent overheating. Selecting the right heat sink type is crucial for ensuring optimal performance and reliability. Here, we’ll discuss the different types of heat sinks available and their suitability for various applications.

1. Passive Heat Sinks: Passive heat sinks rely on natural convection to dissipate heat. They are simple, cost-effective, and suitable for low-power applications. Passive heat sinks are commonly used in desktop computers, LED lights, and other electronic devices where space and airflow are adequate.

2. Active Heat Sinks: Active heat sinks incorporate a fan or other cooling mechanism to enhance heat dissipation. They are more efficient than passive heat sinks and are ideal for high-power applications or environments with limited airflow. Active heat sinks are commonly used in servers, high-performance computers, and industrial equipment.

3. Extruded Heat Sinks: Extruded heat sinks are made by extruding aluminum or copper into a desired shape. They are lightweight, cost-effective, and suitable for a wide range of applications. Extruded heat sinks are available in various shapes and sizes to accommodate different cooling requirements.

4. Bonded Fin Heat Sinks: Bonded fin heat sinks consist of fins bonded to a base plate. They offer excellent thermal performance and are suitable for applications requiring high efficiency. Bonded fin heat sinks are commonly used in power supplies, amplifiers, and other electronic devices where efficient heat dissipation is critical.

- Managing Your Digital Objectives – Short and Long-Term

- Energy Managment and Efficiency for Reducing Costs

5. Stacked Fin Heat Sinks: Stacked fin heat sinks feature multiple layers of fins stacked on top of each other. This design increases the surface area for heat dissipation, making stacked fin heat sinks highly efficient. They are used in high-power applications where space is limited, such as in automotive electronics and telecommunications equipment.

6. Liquid Cooling Heat Sinks: Liquid cooling heat sinks use a liquid coolant, such as water or a specialized fluid, to absorb and dissipate heat. They are highly efficient and suitable for applications requiring precise temperature control. Liquid cooling heat sinks are commonly used in high-performance computers, data centers, and other applications where traditional cooling methods are insufficient.