If someone asks you to name the factor that has a significant impact on the environment, what would be the answer? Yes, it will be none other than electronic business. Electronic devices have helped a lot in giving a new shape to the world.

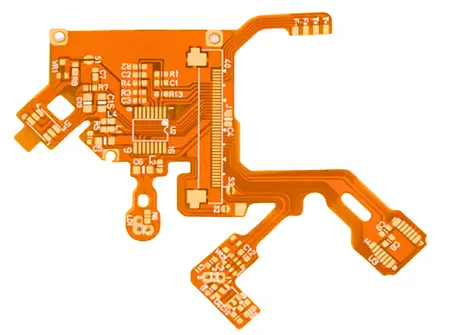

The devices have helped a lot in shortening many tasks to a great extent. But, at the same time, they have impacted the surroundings adversely. By delving into the realms associated with the manufacturing of circuit boards, reputed flexible PCB manufacturers are switching to sustainable practices.

Before moving ahead, it will be good to know the way the dedication of the PCB industry towards the environment.

Did Traditional PCB Manufacturing Result in Environmental Pollution?

The dedication of the PCB manufacturing process to the environment seems a bit questionable. Highly complicated processes of carrying out the procedures were inclusive of the use of toxic solvents and chemicals.

Some of the most commonly used ones included formaldehyde, lead, and dimethyl formamide. The etching processes related to traditional PCBs were inclusive of higher concentrations of copper, tin, nickel, chromium, and many more.

Along with polluting the environment adversely, the hazardous wastes exposed workers to carcinogens and chemicals. It also resulted in causing high reproductive harm. With time, flexible circuit manufacturers changed their ways toward sustainable ways of processing.

Switching on to great activities has prevented the environment from further harm. A few of them are:

- Abandoning the use of highly toxic materials

- Checking supply chains

- Discovering environmentally friendly alternatives

At the time of selecting the right type of PCB manufacturer, it is advisable to check if it is compliant with the REACH and RoHS regulations. These regulations have allowed the PCB industry to work towards a highly sustainable future.

What Makes Green Practices in Flexible PCB Manufacturing Beneficial?

Almost all electronic devices, including laptops and medical equipment pieces, make use of flexible PCBs. That is why demand for environmentally friendly production methods is also increasing rapidly.

Green practices in the PCB business focus on the wide use of raw materials for waste management. Below are some reasons that persuade flexible PCB manufacturers to go with sustainable practices…

Sustainable Flex PCB Manufacturing Practices

The production of waste is a matter of concern associated with the manufacturing of PCBs. It not only hampers the environment, but also human health. The utilization of lean techniques is assisting in waste elimination.

These procedures are also helpful in streamlining the process of production process. Flexible PCB manufacturers can reduce the amount of trash. Recycling programs are helpful in proper waste scrapping.

It is a fact that manufacturers are accountable for their products even after their lives are over. The disposability factor is a must to take into consideration while carrying out manufacturing.

This makes the flexible printed circuit manufacturers accountable in case of every stage related to production. Through proper planning, producers can ensure proper disposal and recycling of components.

It helps in the further promotion of some exclusive, environmentally friendly procedures of flexible PCB manufacturing.

Green Flexible PCB Manufacturing

Making proper utilization of resources is one of the greatest steps in manufacturing a product. Similarly, with initiatives related to flexible PCB manufacturing, it is expected that sustainable resources will be utilized at the maximum level.

Frequently, lead-based solders and brominated retardants are used at the time of manufacturing traditional PCBs. Both are highly hazardous to nature. Taking this point into high consideration, flexible PCB manufacturers are on their way to making use of environmentally friendly materials.

Recyclable substrates, solder, and lead-free laminates help a lot in enhancing end-to-end recycling. They are also helpful in reducing the amount of hazardous waste. There are lots of steps involved in flex PCB manufacturing with water.

From cleaning to etching, water is required in sufficient amounts. To reduce unnecessary waste of water and avoid the devastating effects of pollution, proper steps are required. That is why present-day flexible circuit PCB manufacturers prioritize responsible water management programs.

Making use of eco-friendly cleaning products will make it easy to flex PCB manufacturing.

Does Flexible PCB Manufacturing Assure Restriction of Hazardous Materials?

Carrying out the project of flexible PCB manufacturing can fetch the best outcomes, provided green technologies are utilized. Organizations with valid certifications will be in a favorable position to carry out ethical business practices.

Flexible PCB manufacturers, having a good reputation in the market in most cases, comply with the Restriction of the Use of certain Hazardous Substances. As it limits the use of toxic materials, high-rate protection of the environment can also be expected.

Do Green Practices of Flexible PCB Manufacturing Assure Longevity?

Carrying out refurbishing and repairing PCBs with a circular economy will be something great. This can help flex circuit board manufacturers decrease the hassle of frequent replacement of parts.

Finally, the production of e-waste will also be diminished. It will also encourage higher longevity of products. One more important point to consider is that designers of printed circuit boards prefer incorporating principles of Design for Environment in their designs.

They make decisions about designing circuits carefully. From locating the components to wiring, every step is carried out properly to reduce waste.

What are a Few Instances of Sustainable Flexible PCB Manufacturing?

The green initiatives in flexible PCB manufacturing are all about going with environmentally sound habits. They help lessen the ecological footprint of the sector. Some of the well-known flexible PCB manufacturers consider a wide range of tactics at the time of producing environmentally friendly PCBs.

Many instances relate to the manufacturing of highly sustainable PCBs for the safety of the environment and mankind. They are:

- PCB additive manufacturing – Technologies related to 3D printing are less harmful to the environment. 3D printing brings about a small amount of waste in flexible PCB manufacturing.

- Paper-type PCBs – These types of PCBs are recognized to prevent further harm to the environment. As papers degrade quickly, their usage is justified.

- Using lead-free PCBs – The eradication of lead-based soldering has helped lessen the dangers associated with electronic waste in nature.

- Use of halogen-free laminates – Halogen is highly hazardous to human health and the environment. The use of halogen-free laminates is encouraged to get rid of these components.

Summary

Finally, it is very critical to consider the fact that the utilization of sustainable practices may prove to be ever-changing. Flexible PCB manufacturers having a good reputation can easily give a boost to launching new PCBs, thus demonstrating a commitment to sustainability.