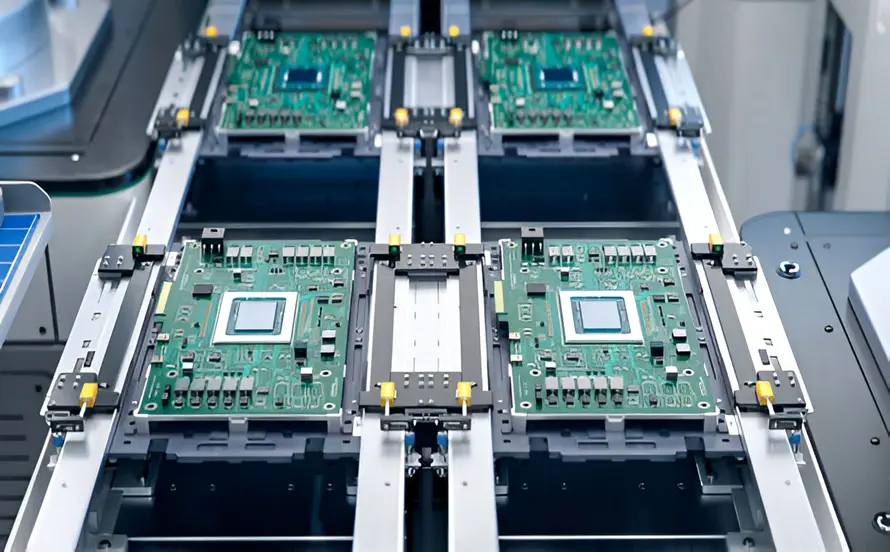

Printed Circuit Boards or PCBs, have revolutionized the electronics industry with their significance in connecting components to actualize important functions. They connect electronic components both physically and electrically. Having a reliable PCB will help ensure that the individual component will perform as intended. The overall device system depends on both the components and the PCB that hold them together to be able to function effectively. In this article, we will explore the concept of Turnkey PCB assembly and its importance to your PCB project.

China PCB fabrication and assembly suppliers are top-notch in providing various printed circuit board solutions. Their superiority is owed to their consistency in offering affordable, quality, and fast manufacturing services that other competing companies cannot surpass. Another key attribute of China PCB manufacturing services is flexibility. Customers can choose from many business arrangements and a vast scale of services, may it be consigned or turnkey, standard or custom mass production, or prototyping only.

What is a Turnkey PCB Assembly?

“Turnkey” is a compound word and expression that means providing products and services that are ready for use. In the PCB assembly, ‘turnkey’ denotes establishing a partnership with a supplier that can do major business processes such as procurement, assembly, and testing of PCBs following customer-specific requirements. This is a common electronics manufacturing business strategy for a more cost-effective and robust solution.

A project often starts with a business case,e which the phase is to decide on a full or partial turnkey or a consigned PCB assembly. Deciding to go for turnkey circuit board assembly is rooted in a business need or requirement. Chinese PCB assembly suppliers have great specialization in PCB manufacturing, which lessens project risks. Aside from that, the customer can analytically choose from multiple suppliers with the best quote, so that one can get the best quality at the lowest price.

What are the Key Steps in a Turnkey PCB Assembly?

Successful Turnkey PCB assembly consists of the following key steps.

Design and Prototyping

PCB Design:

The design of the printed circuit boards can be provided by the customer and reviewed by the assembly supplier for any concerns based on a method called Design for Manufacturing. In some cases, the customer can also request a design service if the PCB assembly supplier has the capability. The design phase consists of finalizing the layout and schematics of the PCB in the Gerber file format.

PCB Prototyping:

Prototyping is the method of assembling small batches to check the design for any issues arising from the design itself or the material, or the assembly.

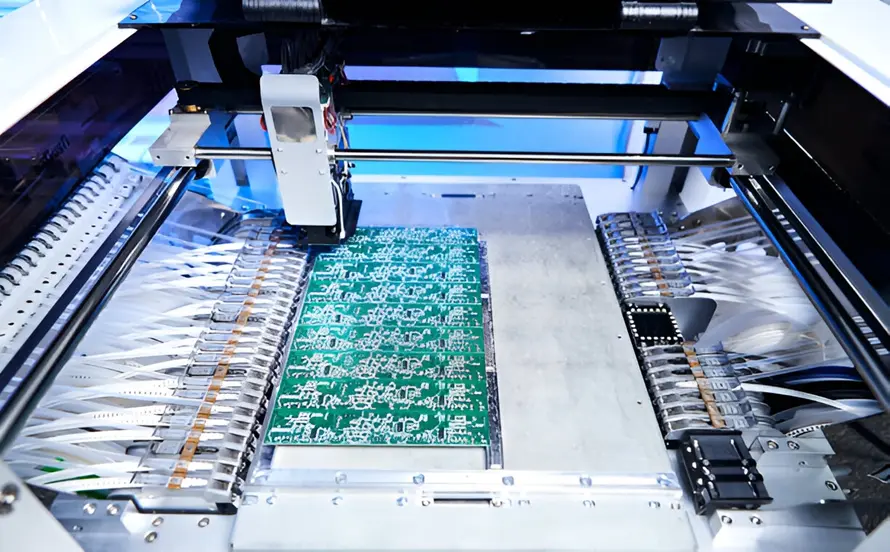

PCB Assembly:

The assembly of printed circuit boards can be done using two methods: Surface Mount Technology or SMT and Through-Hole Technology or THT. THT is an assembly method wherein leaded components are inserted into the holes of the printed circuit boards, after which the terminals are wave-soldered on the other side. SMT, on the contrary, is directly populating the components on the PCB with solder paste screen-printed onto the boards. It is a more recent technique that is well-suited for compact and high-density boards. Below are the major processes during SMT:

Screen Printing:

Solder paste is screen printed on a clean PCB surface using a squeegee and a stencil with apertures.

- Surge Protection in Plain English: When SPD’s Are a Must

- NSW Service & Installation Rules: What Changed in 2025

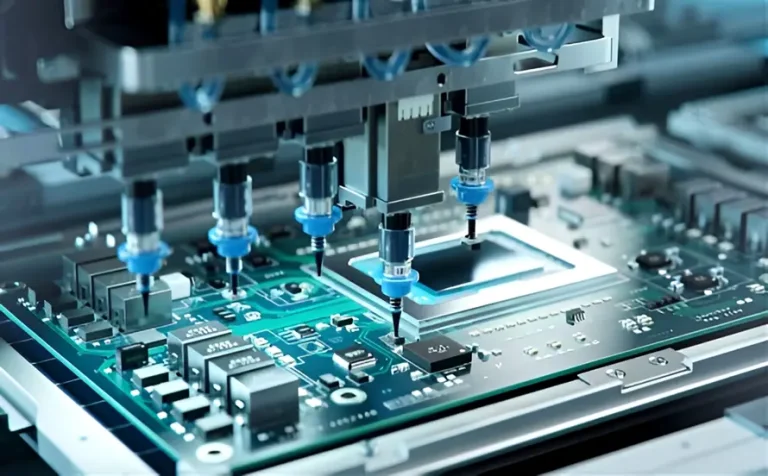

Pick-and-Place:

Components are mounted on the wet solder paste using a high-speed SMT machine.

Reflow Soldering:

The boards are conveyed to a reflow soldering oven to cure the solder paste.

PCB Inspection and Testing:

After through-hole and/or SMT processes, the PCBs should undergo screening using an Automated Optical Inspection (AOI) machine and an X-ray machine. These inspection methods are required to accept or reject PCBs based on defined criteria. The AOI is used to screen out external defects, while X-ray inspection machines are used to detect internal soldering defects such as voiding. Testing is then performed to check for any Open, shorts, or continuity issues.

Why is Turnkey PCB Assembly Important?

The importance of turnkey PCB assembly will be discussed in the following section. This will guide you to gauge whether the turnkey option is the right fit for your PCB project.

Cost Avoidance

Turnkey circuit board assembly can help lessen massive expenditures such as operational, procurement, engineering, and other costs needed for the project. The PCB assembly supplier will handle the procurement of both direct and indirect materials and provide the assembly services. Turnkey printed circuit board assembly suppliers have long-established processing lines—whether it be SMT or through-hole assembly—with quality checkpoints and testing equipment, thus issues and product complaints are less likely to reduce any quality-related costs.

Better Quality.

Another potential benefit of choosing turnkey circuit board assembly is better quality control. As the supplier has more control over the materials and the processes by which the PCBs are assembled, quality measures are already in place. Should there be deviations and issues, the engineering support and technical team are ready to provide analysis and solutions according to their expertise. The turnkey circuit board assembly supplier concentrates on producing boards that are of high quality and good yield, which means fewer problems on the part of the customer.

- Traction Control Sensor TCS: Working and Common Fault Signs

- Motion Encoder: Understanding How It Tracks Precision

Early Time-to-Market.

If you want your project to be expedited to meet a certain timeline, turnkey circuit board assembly is a good decision in shortening the duration of your project. This is because you can centralize your contact to a single supplier who will take care of both procurement and assembly, rather than selecting, qualifying, and communicating with several suppliers to do the job. Turnkey board assembly reduces the hassle of multiple communication exchanges, may they be related to quotation requests, parts inquiries, and technical discussions. Concerning worldwide suppliers, PCB assembly services in China are prominent due to their efficient and world-class logistics system, allowing for faster deliveries and product transfers.

Better Technical Expertise.

From project feasibility to product development and mass production, a technically equipped turnkey printed circuit board assembly supplier has the core competencies to support and build products that are of good performance and quality. Due to extensive technical experience, the turnkey PCB assembly supplier already has an existing structured approach to qualifying PCB products, rectifying issues, and maintaining machines.