In the world of electronics, precision is paramount, especially when amplifying small signals in noisy environments. The instrumentation amplifier (in-amp) is a cornerstone component for engineers and technicians tackling high-accuracy measurement challenges. Whether you’re designing medical devices, industrial control systems, or data acquisition setups, instrumentation amplifiers deliver unmatched precision, stability, and noise rejection. This guide dives into the design, functionality, performance, and applications of instrumentation amplifiers, addressing common pain points like signal integrity and ease of use, while helping you choose the right in-amp for your project.

What is an Instrumentation Amplifier?

An instrumentation amplifier is a specialized differential amplifier with input buffer amplifiers, eliminating the need for input impedance matching. This makes it ideal for measurement and test equipment where small differential signals must be amplified accurately while rejecting common-mode noise. Key characteristics include:

- Low DC Offset: Ensures accurate output signals.

- Low Drift: Maintains stability over time and temperature.

- Low Noise: Perfect for amplifying weak signals.

- High Open-Loop Gain: Provides robust signal amplification.

- High Common-Mode Rejection Ratio (CMRR): Suppresses unwanted noise.

- High Input Impedance: Prevents loading of the input signal source.

- Zero Common-Mode Gain: Amplifies only the differential signal.

- Single Resistor Gain Adjustment: Simplifies gain tuning.

These features make instrumentation amplifiers the go-to choice for applications requiring precision and reliability.

Design and Functionality

The classic instrumentation amplifier design consists of three operational amplifiers (op-amps):

- Input Buffer Stage: Two op-amps buffer the input signals, providing high input impedance and low output impedance to preserve signal integrity.

- Differential Amplification Stage: A third op-amp amplifies the difference between the buffered inputs, with gain set by a resistor network, particularly the gain resistor (Rgain).

- Output Stage: Delivers the amplified signal with appropriate impedance matching.

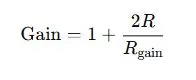

The gain is calculated as:

Where R represents other resistors in the circuit, typically equal. This design allows easy gain adjustment via a single resistor, streamlining circuit design. For gains above +6 dB, a two-op-amp configuration can be used to reduce component count.

Performance Characteristics

Instrumentation amplifiers excel due to their superior performance metrics:

| Feature | Description |

|---|---|

| High CMRR | Rejects common-mode signals (e.g., noise) while amplifying differential signals. |

| Low Noise | Ideal for amplifying small signals with minimal distortion. |

| High Input Impedance | Prevents signal source loading, preserving signal integrity. |

| Low Offset and Drift | Ensures accuracy and stability over time and temperature variations. |

These attributes make in-amps ideal for precision signal amplification in demanding applications.

Applications of Instrumentation Amplifiers

Instrumentation amplifier applications span multiple industries:

- Medical Devices: Amplifying bio-signals in ECG, EEG, and blood pressure monitors.

- Industrial Process Control: Monitoring physical parameters like temperature, pressure, and flow.

- Data Acquisition Systems: Ensuring accurate sensor measurements.

- Test and Measurement Equipment: Used in oscilloscopes, multimeters, and other precision instruments.

Leading manufacturers like Texas Instruments (TI) and Analog Devices offer a range of in-amps tailored to these applications.

How Does an Instrumentation Amplifier Work?

An instrumentation amplifier amplifies the voltage difference between two input signals while rejecting common-mode signals. The input buffers isolate the input signals from the differential amplification stage, ensuring high input impedance and signal fidelity. The gain is set by adjusting the Rgain resistor, offering flexibility across various applications.

Advantages of Instrumentation Amplifiers

Compared to standard operational amplifiers, in-amps offer:

- High Precision: Accurate amplification of differential signals.

- Ease of Gain Adjustment: Single resistor simplifies gain tuning.

- Noise Rejection: High CMRR suppresses common-mode noise.

- Stability: Low offset and drift ensure long-term reliability.

These benefits make in-amps superior for high CMRR amplifier applications.

Technological Advancements in Instrumentation Amplifiers

Modern instrumentation amplifiers have evolved significantly:

- Zero-Drift Technology: Minimizes offset and drift for enhanced stability.

- Input Overvoltage Protection: Handles input voltages up to ±60 V, ideal for harsh environments.

- Wide Bandwidth and Low Noise: Bandwidths up to 28 MHz and noise as low as 1 nV/√Hz for high-frequency applications.

- Miniaturization: Compact packages like 3×3 mm WSON for space-constrained designs.

- Low Power Consumption: Micro-power options as low as 50 µA for battery-powered devices.

These advancements expand the versatility of low-noise instrumentation amplifiers.

Popular Instrumentation Amplifier Models

Here are some widely used in-amp models:

| Model | Manufacturer | Features |

|---|---|---|

| INA128 | Texas Instruments (TI) | High precision, low power |

| AD8221 | Analog Devices | High CMRR, low noise |

| LT1167 | Linear Technology | Ultra-high CMRR, low offset |

| MAX4194 | Maxim Integrated | Balanced performance |

These models cater to diverse instrumentation amplifier applications.

Choosing the Right Instrumentation Amplifier

When selecting an in-amp, consider:

- Gain Range: Match the required amplification level.

- Bandwidth: Ensure compatibility with signal frequency.

- Noise Performance: Choose low-noise models for small signals.

- Power Requirements: Verify voltage and current needs.

- Package Size: Select appropriate packaging for your design.

Frequently Asked Questions

- What is the primary use of an instrumentation amplifier?

It amplifies small differential signals while rejecting common-mode noise, ensuring high precision and stability. - How do you adjust the gain of an instrumentation amplifier?

Gain is adjusted by changing the Rgain resistor in the circuit. - What are common applications for instrumentation amplifiers?

They are used in medical devices, industrial control, data acquisition, and test equipment. - Why are instrumentation amplifiers better than standard op-amps for certain applications?

They offer higher input impedance, better CMRR, and lower noise, making them ideal for precision measurements. - Can instrumentation amplifiers be used in high-frequency applications?

While primarily designed for low-frequency signals, some modern in-amps support higher frequencies, though performance may not match RF amplifiers.

Related Resources

To learn more about the fundamentals of operational amplifiers, which form the basis of instrumentation amplifiers, check out this insightful article on Operational Amplifier Basics, Working Principle, and Amplifier Circuit.

Conclusion

The instrumentation amplifier is a vital tool for engineers seeking precision signal amplification in challenging environments. Its robust design, high CMRR, and ease of use make it indispensable in medical, industrial, and measurement applications. By understanding its functionality and advantages, you can leverage in-amps to enhance your designs and achieve superior performance.