High-speed communication networks are the backbone of our digital infrastructure. From seamless video calls to instant file transfers, we rely heavily on these networks to keep us connected.

However, with increasing complexity and the growing demand for faster and more reliable connections, network failures can have a significant impact on businesses and individuals alike. To safeguard these crucial networks, electrical failure analysis becomes essential.

Εlectrical Failure Αnalysis involves understanding the root causes behind network failures, diagnosing the issues, and implementing effective solutions.

By following a systematic approach, businesses can minimize the risk of downtime, identify and address network vulnerabilities, and enhance the overall performance of their communication networks.

7 Essential Steps Involved in Electrical Failure Analysis

Step 1: Identification

The first step in electrical failure analysis is the identification of the problem. This may involve receiving reports from end-users, detecting abnormal network behavior, or monitoring performance metrics. Detailed logs and documentation serve as valuable resources in identifying when and where the failure occurred.

For example, imagine a high-speed communication network experiencing intermittent outages. By gathering reports from affected users and analyzing historical data, the identification step enables the team to pinpoint the specific areas or components responsible for the failures.

Step 2: Data Collection

Once the problem is identified, the next step is to collect relevant data for analysis. This includes capturing network logs, system performance metrics, and any other relevant information that helps in understanding the failure scenario. Data collection is crucial as it provides insights into the conditions before the failure and helps create a comprehensive view of the network’s health.

Modern tools and software solutions provide real-time monitoring and data collection capabilities, significantly simplifying this step. By collecting a wealth of data, network engineers can gain valuable insights into the root causes of electrical failures.

Step 3: Testing

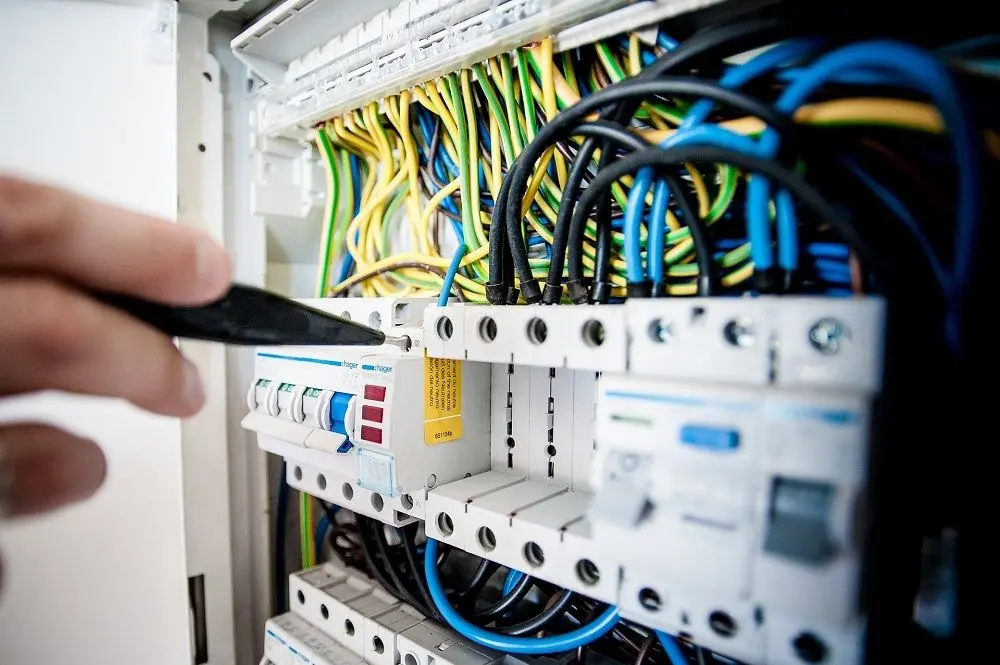

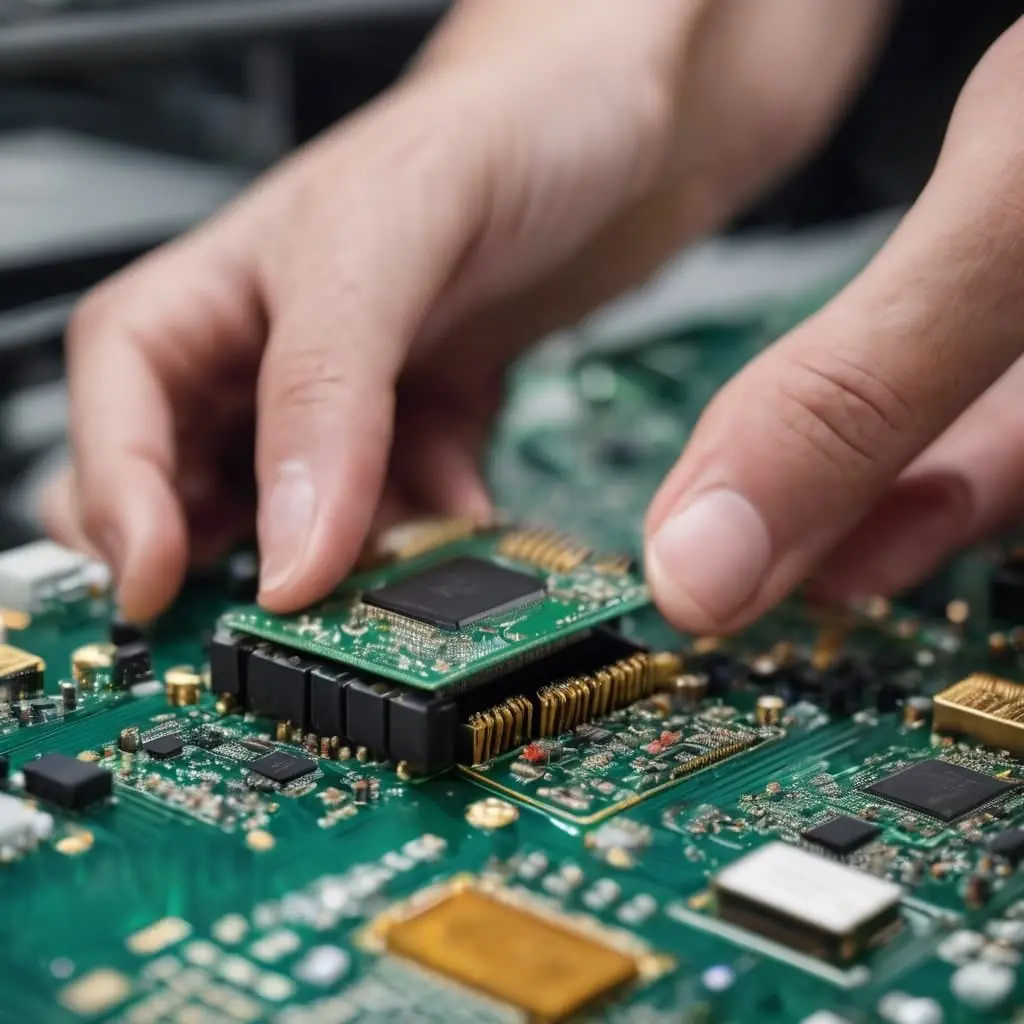

Testing is a pivotal step in electrical failure analysis as it helps narrow down potential causes. Rigorous and detailed testing involves isolating different components or areas of the network to determine their functionality and reliability. This may include examining cables, connectors, and electrical components, and verifying the integrity of power supply sources.

For instance, if the network failures are suspected to be caused by faulty cables, testing each cable individually for conductivity, insulation integrity, and signal transmission can help identify the faulty ones.

Step 4: Analysis

Once data is collected and testing is completed, the analysis phase begins. This step involves thoroughly examining the data to identify patterns, anomalies, and potential causes of the failure. Advanced analytical techniques, such as statistical analysis and data visualization, can aid in deciphering complex data sets and identifying hidden patterns.

Through analysis, network engineers can gain insights into the root causes of electrical failures, such as power surges, signal interference, or equipment malfunctions. This understanding forms the foundation for the subsequent steps in the electrical failure analysis process.

Step 5: Root Cause Determination

Determining the root cause of network failures is crucial for implementing effective corrective actions. This step requires a deep understanding of the data collected, the network architecture, and the potential interdependencies between different components.

- Complete Guide to Electronics Engineering

- Traction Control Sensor TCS: Working and Common Fault Signs

Let’s consider a scenario where network failures are traced back to an inadequate power supply. By thoroughly analyzing the data, it may be discovered that certain areas of the network experience frequent power fluctuations, leading to intermittent connectivity issues. Identifying the root cause enables engineers to address the underlying problem rather than merely treating the symptoms.

Step 6: Corrective Action

With the root cause identified, it’s time to implement corrective actions to resolve the electrical failures. This phase often involves repairs, component replacements, software updates, or infrastructure enhancements. It is imperative to have a proactive approach to corrective actions, ensuring that they not only address the immediate issues but also prevent similar failures from occurring in the future.

For example, if the failure analysis reveals loose connections as the root cause, the corrective action may involve tightening all cable connections throughout the network and implementing routine maintenance practices to prevent similar issues in the future.

Step 7: Preventive Measures

The final step in electrical failure analysis is implementing preventive measures to reduce the risk of future failures. This may include implementing redundancy mechanisms, improving network resilience, regularly monitoring system health, and conducting periodic maintenance.

Preventive measures not only mitigate the risk of downtime and network failures but also help businesses optimize their network performance. By taking a proactive approach to prevent potential failures, businesses can ensure uninterrupted high-speed communication, keeping their operations running smoothly.

Exploring Different Viewpoints

Efficiency vs. Cost-effectiveness

One viewpoint to consider is the trade-off between efficiency and cost-effectiveness in electrical failure analysis. While businesses aim for optimal network performance, they also strive to minimize costs associated with analysis and preventive measures.

- Crane Electrical Systems: Safe, Intelligent, and Efficient Operation

- Electrical Installation Guide: Wiring, Protection & Safety Standards

Achieving a balance between these two aspects can be challenging, as more comprehensive analysis and preventive measures often involve higher costs. However, cutting corners on analysis and preventive measures can lead to recurring failures and increased costs in the long run.

For example, investing in advanced testing equipment and partnering with specialized service providers may initially have higher upfront costs.

However, these investments can significantly reduce the overall cost of failures and improve efficiency over time by minimizing downtime and enhancing network reliability.

Human Error vs. Technical Malfunctions

Another important viewpoint is the distinction between human error and technical malfunctions as the source of electrical failures.

While technical malfunctions can be attributed to equipment failures, power fluctuations, or environmental factors, human error is often a contributing factor as well.

It is crucial to assess and address both human and technical aspects to effectively analyze failures and implement preventive measures.

For instance, a misconfiguration in a network device resulting from human error can lead to network disruptions. By conducting thorough analysis and promoting employee training and awareness programs, businesses can identify potential human error risks and mitigate them to prevent future failures.

Personal Experiences and Anecdotes

Throughout my career in network engineering, I have encountered numerous instances where electrical failure analysis played a pivotal role in maintaining the reliability of high-speed communication networks. One such experience involved a network outage that appeared to be caused by a faulty network switch.

Through detailed analysis and testing, we discovered that the underlying cause was a power quality issue, leading to intermittent functionality of the switch.

By rectifying the power supply problem and implementing preventive measures, we not only resolved the immediate issue but also prevented similar failures in the future.

Another memorable incident involved network failures in a remote location. By collaborating with Wintech Nano and their experts in electrical failure analysis, we were able to create a comprehensive diagnostic plan and identify a critical misconfiguration that was causing the disruptions.

Through tailored corrective actions and subsequent preventive measures, we not only restored network functionality but also enhanced the overall reliability of the communication network in that area.

Conclusion

Effective electrical failure analysis is essential for safeguarding high-speed communication networks.

By following the seven essential steps of identification, data collection, testing, analysis, root cause determination, corrective action, and preventive measures, businesses can minimize downtime, mitigate risks, and ensure the smooth operation of their networks.

It is important to consider different viewpoints, strike a balance between efficiency and cost-effectiveness, and address both human and technical aspects to create a balanced strategy for electrical failure analysis.

With the right approach and utilizing advanced tools and solutions, businesses can stay at the forefront of network reliability and deliver seamless connectivity to their users.